There are pros and cons of using 48v DC motors in industrial, automotive applications. While they have more power - on the same score, able to fling fitments around with some serious intent On top of that, they do so without spewing toxic pollutants into the atmosphere like gas engines. Nonetheless, these kinds of motors can cost a lot to produce and install and are not ideal for use in very warm conditions.

However, once you open up a 48v DC motor to the naked eye we realized that there was nothing simple about it when talking specifically about set of wires because all they did was pass electricity so the engine would turn on. The electricity flow inside the wires produces a magnetic field that interacts with other magnets in motor casing and causes movement.

There are challenges in integrating 48v DC motors into modern automotive systems. There are times when smooth operation requires effective communication among the motor and vehicle. This will certainly involve the motor telling the car how quickly it is turning and its power draw, requiring some serious computer programming to be developed.

The path, however, is not an easy one to follow but the role these motors are playing in supporting sustainable transportation practices cannot be ignored. Moving away from gas and into an electric propulsion technology can help combat air pollution that leads to climate change. Additionally electric-vehicles that are smoother and almost silent when contrasted with gas-fueled vehicles.

The overview above amplifies that 48v DC motors are a unique and crucial solution in the world of electrical machinery requirements. They have the potential to significantly ease our move toward a cleaner and more sustainable process, which makes continued improvements in their design and implementation essential.

customer support team is always available to assist with any queries from customers. We have the 99.4 percent response rate less than five 48v dc motor, and the 48.6% response rate within under five minutes. R D engineers also hand to help customers with technical issues online.

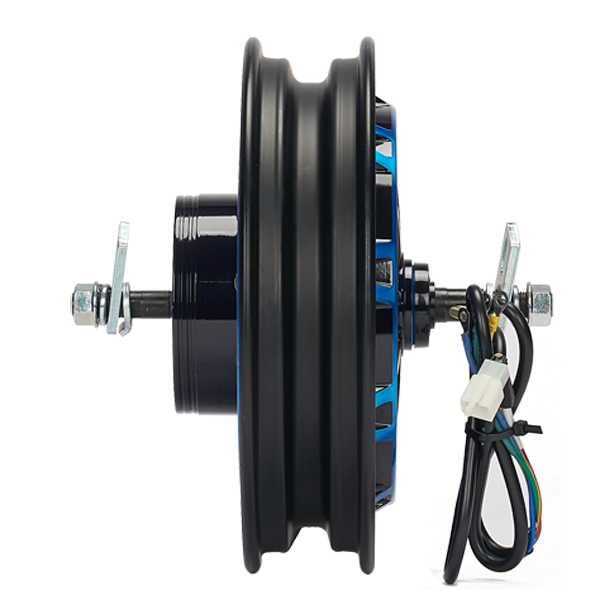

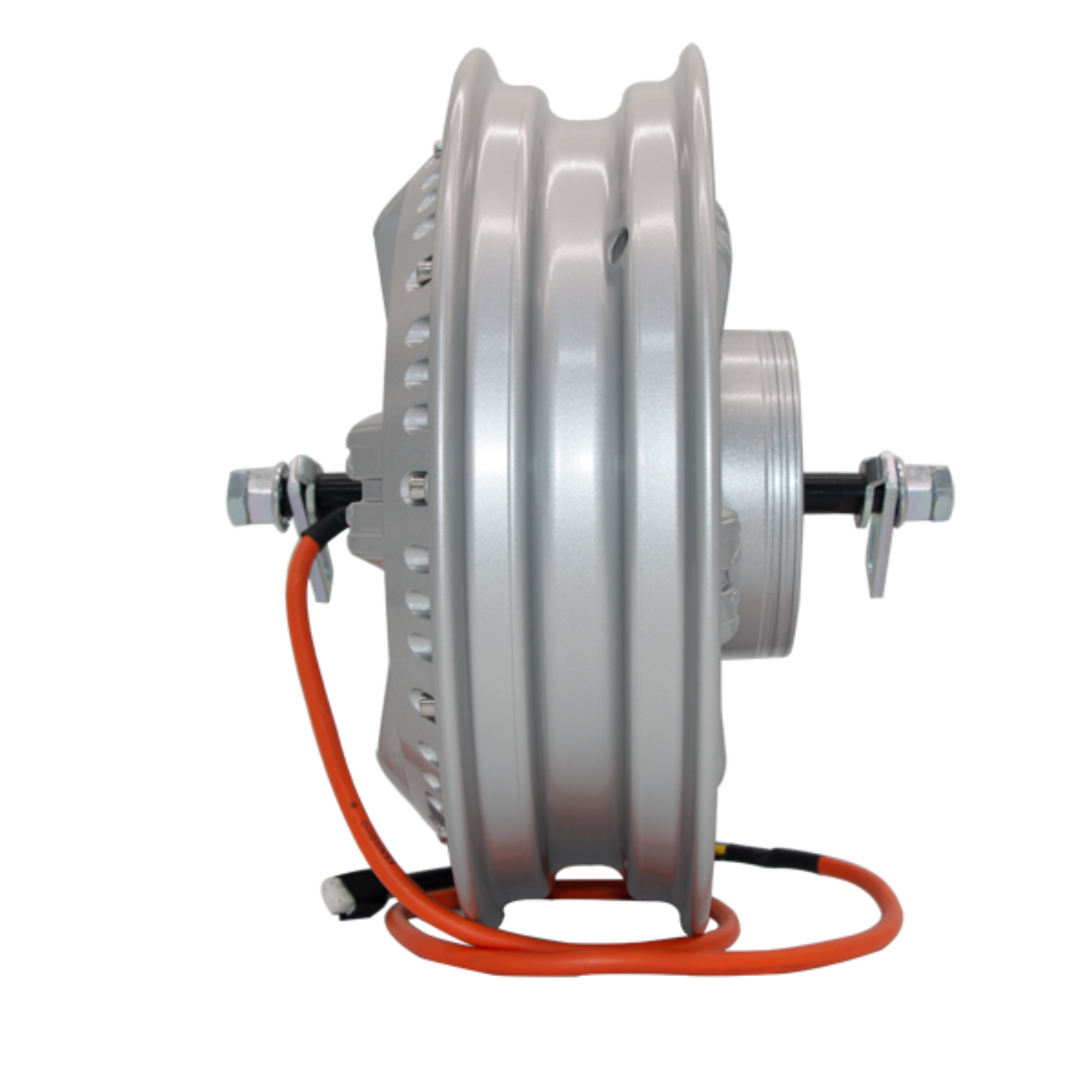

Lingming Motor has focused manufacturing, production research various brushless DC hub motors more than 20 years. factory covers area of more than 10,000 square meters. It has the capacity produce daily between 15,000 to 20,000 units. 48v dc motormore than 20 development engineers, with an average more than 12 years R D expertise.

company mainly produces electric two-wheeled three-wheeled motors controllers for vehicles. motors have superior torque, low noise energy consumption, as well as high efficiency. can design products according to requirements our 48v dc motor. also offer a one-year warranty service. Any issues with product quality that arise during period can be repaired or replaced at no cost. Our products are widely exported to many countries around the world.

motors undergo professional quality testing every process from pre-production through production all way to post-production, ensure that each spare part manufactured with high quality. products offer have been tested passed CE, CQC, ISO9001 certifications, the company has 48v dc motorpatents guarantee the creation of new customized products.