The Domain of Electric DC Motors

Electric motors are incredible tools that bring life to objects that require them. Among all types of electric motors, the electric DC motor stands out as one of the most essential due to its widespread use. From the automotive industry to toys and industrial machinery, DC motors find applications in various fields. Let's delve deeper into the world of electric DC motors by exploring what they are, how to select the right one for your needs, and the significance of proper maintenance.

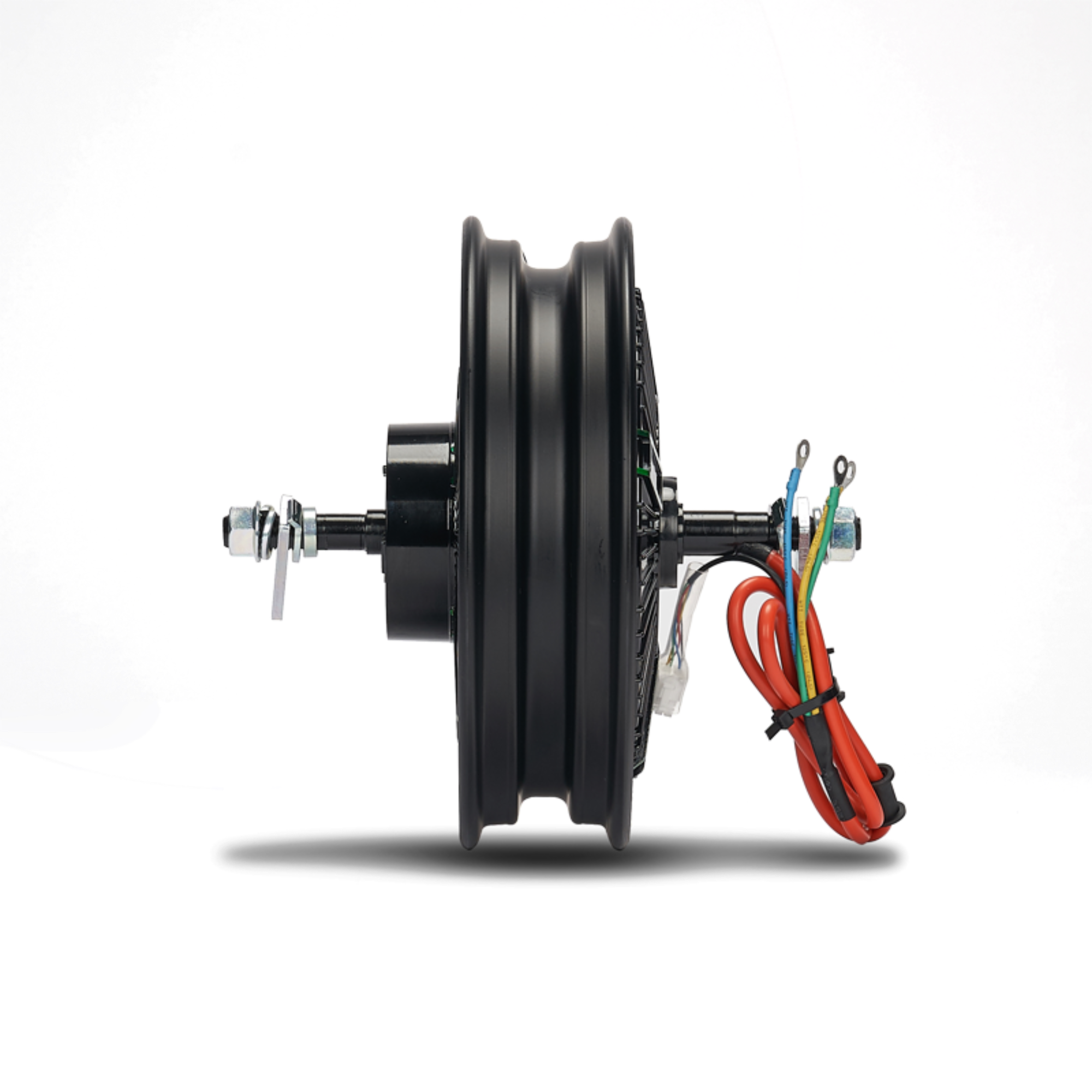

At the core of an electric DC motor's operation is the utilization of direct current to initiate movement. The motor comprises two main components: the stationary stator and the rotor, which rotates continuously. This rotational motion is achieved by passing electricity through wire coils in the armature. The flow of electricity creates a magnetic field that interacts with the stator's field, resulting in the rotation of the rotor. This continuous rotation causes the armature to move back and forth, thus generating the motor's rotation.

Choosing the right DC motor for your specific task is crucial to avoid issues related to underperformance or overperformance. Factors such as motor voltage, current, dimensions, weight, required speed, and torque output should all be considered when making a selection. For example, referring to the device's manual can help determine its voltage requirements. It's important to note that the motor's size corresponds to its power but also affects its weight. A larger motor will be heavier, which may impact its portability between different tasks.

Maintenance plays a vital role in determining the lifespan and efficiency of any electrical device, including the DC motor. Regular maintenance tasks such as cleaning the motor, lubricating its components, and inspecting for loose or damaged connections are essential. Promptly addressing early signs of overheating, unusual noises, or vibrations is crucial to prevent damage.

Electric DC motors are indispensable components of our electric-powered future. Understanding their functionality, selecting the appropriate motor for each application, and implementing proper maintenance practices not only prolong their operational life but also contribute to environmental sustainability by reducing the need for premature replacements.

customer support team is always available to assist with any queries from customers. We have the 99.4 percent response rate less than five electric dc motor, and the 48.6% response rate within under five minutes. R D engineers also hand to help customers with technical issues online.

Lingming Motor has focused manufacturing, production research various brushless DC hub motors more than 20 years. factory covers area of more than 10,000 square meters. It has the capacity produce daily between 15,000 to 20,000 units. electric dc motormore than 20 development engineers, with an average more than 12 years R D expertise.

company manufactures electric dc motormotors with electric wheels, two three wheels and controllers. motors manufacture feature characteristics like silence and high torque, efficient energy use as well as high efficiency. can customize products according to specifications of customer. also offer a one-year warranty service. Any issues with product quality that arise during the warranty period are fixed at no cost. Our products have been widely exported to many countries around the world.

motors subjected to rigorous quality checks every stage production starting from pre-production all way to post-production. guarantees that every spare part is made a high standard. company has CE, CQC and ISO9001 certifications. company also has multiple patents the electric dc motorcustom-designed innovative products.